Please note: This project was submitted by FrightProps customer Darin Cleveland. It has not been verified by FrightProps and we cannot provide support on this project.

Description:

This instructional will show you how to build an air driven rig that will lower and lift a prop on a piece of string or rope (such as spiders, masks, or decapitated clown heads).

Note: if this rig is intended to lower a prop within touching range of a person, there are extra safety precautions which must be used when installing this rig. Please see the bottom of the instructional for these safety precautions.

Required Tools:

- Tape measure

- Welder

- Metal saw (electric powered or hand saw. Electric is strongly advised)

- Metal grinder

- Drill (a drill press is recommended for straight holes)

Required Parts:

- Fourteen feet of ½ inch square steel tubing (also can be found in almost any hardware store)

- One, 2inch long bolts of 1/4th inch diameter. (any sized bolt will work so long as it fits within the 1/2inch steel tubing but the thicker the bolt is, the more stable it will be. This is just the bolt used in this specific example. Apply this note for all nuts and bolts mentioned in this instructional)

- one lock nut of the same diameter

- two washers to fit the bolt

- a power cord or trigger to power the cylinder solenoid

- an air compressor

- rope, thread, or string.

FrightProps required parts:

- an air cylinder (cylinder used in instructional is a 4inch stroke 1 1/16 bore double-acting universal mount FrightProps cylinder (non-rotating is recommended) (/1-1-16-inch-bore-double-acting-universal-mount-cylinder.html ). This bore of cylinder exerts more power than necessarily needed, so cylinders of smaller bore may be alternatively used.)

- A FrightProps cylinder hook-up starter kit (single acting, 1/4inch tubing, 12VDC or 110VAC, depends on your power source. /cylinder-hook-up-starter-kit-single-and-reverse-acting.html )

- a rod clevis (if using the same cylinder, 5/16 – 24 /rod-clevis.html )

- 3 clevis mounting brackets (if using the same cylinder, .25in hole, .11in thickness /clevis-mounting-bracket.html )

- quick connect with push on, ¼ tube size (to connect the system to your air compressor. /quick-connect-barrel-with-push-on-for-1-4-airline.html )

- Two male connector push-ons with flow control, 1/4in tube /male-connector-push-on-with-flow-control.html

Optional Parts:

- air regulator /regulator-1-4-ports.html

- any trigger, from motion sensor, step mat, or button activated.

- Velcro for prop attachment (more on it later)

*Total cost: approximately $150

*not counting the air compressor, air regulator, wood base board, or prop you wish to attach to the rig.

Important Notes:

- Please read through all steps before starting this project.

- Refer to Step 10 before deciding where and how you are going to mount your rig.

- Remember that pneumatics can extort a lot of force and can be dangerous. Maintain a safe distance and keep your pneumatic rig away from objects and other people while it is powered on. When testing this prop for the first time, twist the flow control connectors almost all the way clockwise to test it at its slowest speed.

- Practice safety when modifying power cords. NEVER modify a power cord when it’s plugged in.

Step 1:

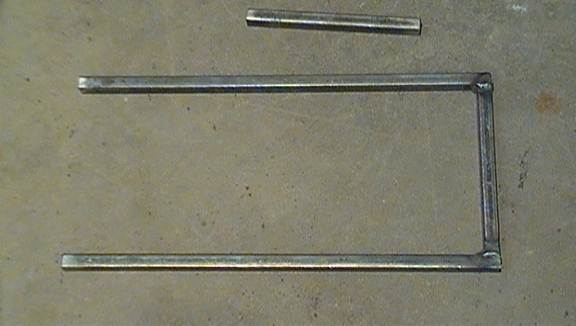

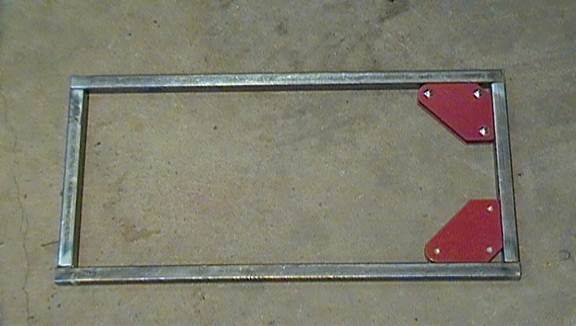

Cut two 14inch segments out of your 1/2inch steel tubing, and two 6inch segments. Take the two 14inch segments and one 6inch segment and weld them into a U-shape as seen bellow.

When you’re done, go ahead and drill holes in each of the corners of the U. You’ll use these holes to later mount your rig onto a base platform.

Builder’s tip: keep the second piece of 6inch segment between the open ends of the U to guide you and keep the 14inch pieces parallel to each other. 90degree magnets are also very helpful.

Step 2:

Cut two 18inch long pieces of 1/2inch steel tubing. Weld them in the center of the U’s “bottom” edge with a gap between the two pieces large enough to fit a third piece of 1/2inch steel tubing and two washers between them.

Once these pieces are welded on, double check that a 1/2inch piece and two washers will still fit between the pieces (make sure that it’s loose enough for the washers to spin in them, the rig arm will go here). When you have, weld a 3/2inch piece of 1/2inch steel over the top of the pieces, to brace them against each other.

Important note: the example pictures use 20inch long pieces instead of 18. This rig was later converted into a Vertical Lifter Rig (the instructions for building a Vertical Lifter Rig can also be found at FrightProps.com)

Step 3:

Weld the remaining 6inch piece in about the middle of the U.

Cut two pieces about 10inches long from stock of 1/2tubing. Cut the tips off of them so that the ends have a 45degree angle. Afterwards, weld these pieces from the top of the crossbar in the U-piece (45degree edge down) to the outer sides of the two vertically pointing rods.

These pieces are for stability.

Step 4:

Drill holes (equal diameter of the bolt you intend to use) straight through the vertical rods, about one inch down from the crossbar. It’s important that these holes line up so that the rig arm moves straight. It is recommended to use a drill press and drill through both rods in one go.

Step 5:

Now take a 4ft long piece of 1/2inch steel rod. This will be used as the arm. Drill a hole through it 4inches from one end. Drill holes at the far end of the rod as needed to attach the rope/string/thread you will dangle your prop from.

Mount the arm in the rig with the bolt, spacing it in the center of the two rods with the two washers. Use a lock nut to keep the bolt secured. The arm should rotate freely.

Step 6:

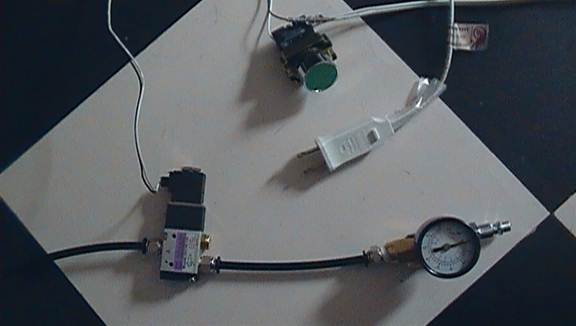

Set up your pneumatic. Attach a rod clevis to the “nose” (the cylinder’s shaft end) and a clevis mounting bracket to that. Attach the two remaining clevis mounting brackets to the “base” (the other end).

Also install two male-connector push-ons with flow control. You’ll need two in order to regulate how fast the cylinder extends and retracts.

Step 7:

Now it’s time to attach the pneumatic. You want to attach the base brackets to the vertical shafts of the rig and the clevis bracket to the underside of the rig arm (keeping in mind that if it’s a ground mounted rig, you don’t want the arm to ever drop below ground level) so that when the pneumatic’s rod is retracted, the arm is lifted, and when the rod is extended, the arm is lowered.

There is a lot of guess and check work here. Use clamps or just your fingers to move the base brackets and the nose bracket to different positions and examine how the arm is rotated with the pneumatic rod retracted and extended.

Keep in mind that as this rig moves, its tip does not only move up and down but forward and back a little, because the arm is moving in a circle. If you mount this rig directly above attraction goers without any direction changing forces (like pulleys or hooks) between the rig and the prop, the prop will move forward and back a bit.

Mounting the cylinder so the arm only moves 30degrees will keep the forward and back motion to a minimum.

Before committing to any permanent welds, when you think you have the right positions, tack weld them in place. Double and triple check that the arm moves to the locations you want it to when extended and retracted.

When you’re confident that you have the right spots, weld firmly in place.

Step 8:

Supply power to your pneumatic. Use your single-acting solenoid (you only need single-acting because gravity will retract your rig for you) and follow the proper instillation/setup instructions found on FrightProps.com.

Which side of the cylinder you connect your “output” hose from the solenoid will depend on how your rig is set up (see step 10). If gravity does not retract/extend your rig as you would like it to, attach weights as needed.

To activate the solenoid, and as a result your pneumatic rig, you need to supply it power. If you bought a 110VAC activated solenoid, you just need to splice a power cord and solder or crimp the wires together. Plugging the cord in will turn the solenoid on and the cylinder will extend. Unplugging it will turn the solenoid off and the cylinder will retract.

Power adapters/transformers will be needed for a 12VDC or 24VDC solenoid. These can be found at FrightProps.com as well.

Naturally, this isn’t very practical, but it’s good for testing. You can install a button (such as shown below), a pressure mat, a motion sensor, or other triggers to activate your pneumatic rig.

Use the push-on connector at the other end of your airline hose. Hook a regulator to that, and an air-compressor hose adaptor to that. Plug it into your air compressor and you now have power to your pneumatic.

It is HIGHLY RECOMMENDED that you use an air regulator here. FrightProps systems are not designed to operate above 120 psi, and pneumatics can be very dangerous when supplied large amounts of pressure.

Step 9:

This is not a stand-alone rig. The arm makes it unbalanced. Use the holes in the base of your rig to attach it to a base platform, such as a wide platform of wood. Chip-wood and plywood work just fine. Make sure that the platform is large, heavy, and stable enough to keep the rig firmly in place when it moves its arm repeatedly.

This is EXTREMELY important when the arm is to be above where people are meant to walk. You don’t want the rig to break off of its platform and fall on someone.

(picture not shown)

Step 10:

There are two ways of using this rig.

First option is to mount the rig in a location in which the arm is above the path where people travel through whatever attraction you are hosting. Bolt it on top of a tall, sturdy crate, or a special built roof or platform. Attach a rope, string, or thread to the end of the arm and a prop on the other end of the string so that when the arm lowers, it drops the prop into view or direct path of the attraction goers.

Because a portion of this rig is directly above people, strict safety protocols must be followed to ensure it does not injure anyone. Please see Important Safety Notes below for said information.

The second option is to mount the rig on the ground, out of sight of the patrons, and have it pull on a string to be strung across pulleys or hooks and indirectly dangle a prop over the path of patrons. You’ll need two hooks or pulleys (hooks will work just as well as pulleys in most cases). Mount one hook above the rig, mount the second hook where you want your prop to drop down from and string your rope/string/thread and prop across. Instead of the arm dropping and the prop being lowered as it would if you mounted it above the patrons, the arm will rise and the prop will be lowered.

This option is inherently safer, as the rig does not need to be mounted high and is not above patrons. Since it is still dropping a tangible prop in front of patrons where they can touch it, some safety protocols still need to be applied. Please see below.

Install the air hoses to the cylinder accordingly. Use the regulator valves to adjust the speed the cylinder extends and retracts. Since gravity will naturally retract the arm, only a single acting solenoid is needed. A double cylinder is used so the air regulators can be used to regulate the retraction and extension speeds.

Important Safety Notes:

If mounted directly above patrons:

- Make absolutely sure that the rig is VERY secure to whatever it is mounted to. If the arm is to pass above where people walk, you must make sure that there is no chance of it falling on them even if someone is to tug on the prop hooked to the arm.

- If mounted so the arm passes above where people walk, mount it so that even when lowered, the arm is out of reach of even tall people.

- Use a line of thread or string or rope that will break if someone pulls on the prop. You want the rope to break sooner than the base you’ve mounted your rig on, as that will send it crashing down on the people. Better yet, do not attach the rope to the rig arm by tying it. Use Velcro. Use the right amount and it will stay on despite the movement but will tear apart sooner than your rig will.

Whether mounted directly above patrons or not:

- Make sure that when the prop is lowered, the top of the prop does not pass below even a tall person’s chin. This is to prevent the chance of someone getting tangled in the rope and being strangled.

- The prop you use has to be both light and soft. Make sure that it has no chance of injuring someone when it drops down. Use something made of foam or light rubber.

- Use an inexpensive prop. There are some people who will steal anything that isn’t nailed down, and a prop held up by a piece of string is no exception.

FINAL NOTES:

- Remember that pneumatics can be dangerous if the right precautions are not taken.

- Make absolutely sure that the rig is receiving less than 120PSI at all times.

- When testing the rig for the first time, make sure all persons are at least five feet away and to the side of the rig (not behind or in-front), and that the area is clear around the rig.

- Make sure that the prop and the base platform are securely attached to the rig before activating it.

- Be sure to regulate pressure or enlarge the base platform so that the rig does not move from its spot when activated repeatedly.

- Inform everyone working around or with the rig about the dangers of it, and safe operation.

- When using this rig for an attraction, be sure that it is placed where it (the rig itself, not necessarily the prop) has no chance of physically striking someone, even if they wander from the attraction’s designated path. It is safer yet to regulate PSI to the minimal force required to lift/drop your prop.