Single, DOUBLE, AND Reverse Acting

Cylinders are available in double acting, single acting, and reverse acting. The most common are double acting and then single acting. Reverse-acting are rarely used.

| Single Acting

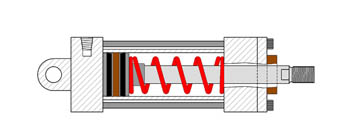

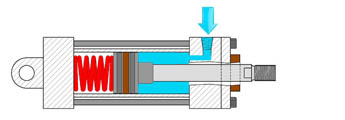

Single acting cylinders provide power only on the extension or "push" stroke. A separate force, usually an internal spring, returns the piston to its original position in preparation for the next stroke. |

|

|

|

|

An internal spring retracts the piston rod when the blind end of the cylinder is exhausted. |

The piston rod is extended by air pressure.

|

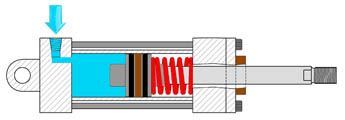

Double Acting Double acting cylinders have dual pressure chambers and provide pneumatic power on both extension and retraction, eliminating the need for a spring. |

|

|

|

|

The piston rod retracts when air pressure is directed to the rod end of the cylinder.

|

The piston rod is extended by directing air pressure to the blind end of the cylinder.

|

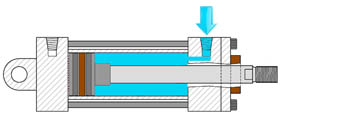

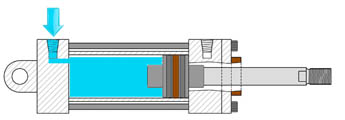

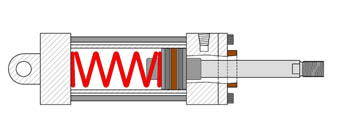

Reverse Acting Reverse single acting designs are similar to single acting, but with the port on the opposite end to provide power only on the retraction or "pull" stroke. |

|

|

|

|

The piston rod retracts when air pressure is applied.

|

Internal springs hold the piston rod in the extended position.

|

BORE SIZE

Bore refers to the inside diameter of the cylinder. The larger the bore the more force a cylinder can exert. Also, as bore size increases so does the shaft diameter making it stronger so that it can handle increased loads.

Here are some PSI (air pressure) to force figures for standard bore sizes. These figures are approximates only and will vary in different applications.

| Cylinder Bore Size | Force Multiplier | Force @ 100psi |

| .75" (3/4) | .4x | 40 pounds |

| 1" | 1x | 100 pounds |

| 1.5" | 1.7x | 170 pounds |

| 2" | 3.1x | 310 pounds |

| 3" | 7x | 700 pounds |

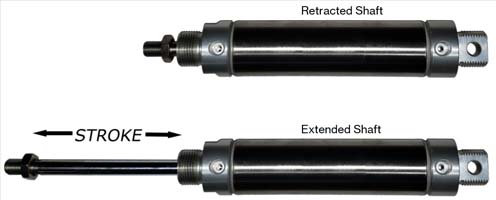

STROKE

Stroke refers to the length that the cylinder shaft extends from the cylinder body. Stroke is sometimes referred to as "throw".

How to determine the right-sized cylinder for your job

Specifying the right cylinder for the right job results in better and longer cylinder performance. And that means lower overall operating costs.

Proper cylinder size selection begins by calculating 1) the weight of the load, 2) the required velocity, and 3) the air pressure used. Let's take a closer look at each of these three factors.

Weight of the load: This is set by the machine design. In order to move the load, you'll obviously need a cylinder that provides force greater than the load. We recommend allowing an additional factor of 25% force over the load to compensate for friction.

Velocity: Velocity is also usually set by machine design, but there's usually some latitude within a range. Low speeds (up to 4 in/sec) require 25% more force than the load, moderate speeds (4 to 16 in/sec) about 50% more and high speeds (greater than 16 in/sec) about twice as much.

Air pressure: You need consistent air flow at the minimum effective pressure to maintain the desired velocity. Operating the cylinder at too high a pressure accelerates seal wear and creates stress on the cylinder. Inconsistent pressure can cause system malfunction or failure.

Next you'll need to determine bore size. Let's look at an example assuming a maximum load of 100 lbs, a minimum velocity of 8 in/sec and a minimum pressure of 60 psi. The velocity is moderate, but the force should be about 50% greater than the load, or 150 lbs. Dividing the force (150) by the pressure (60) gives you a power factor of 2.5. A 2" bore cylinder, with a power factor of 3.1, provides the needed force.