- Home

- Support

- Pneumatics

- Controlling the speed of a cylinder

Controlling the speed of a cylinder

Overview

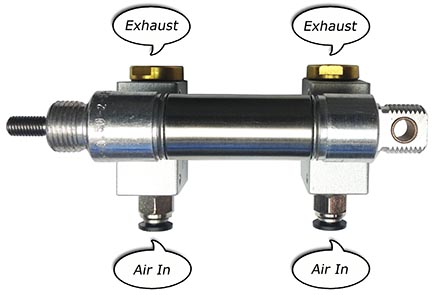

There are several methods to control the extending and retracting speed pneumatic cylinders. We offer Flow Controls, Speed Control mufflers, and Quick Exhaust Valves to accomplish speed control. Double-acting cylinders can have both the out and in stroke controlled and you can mix the different control methods on each port. In reality it is difficult to regulate speed of air cylinder because of the compressible nature of air. So exact speeds are not obtainable but you can get sufficient control for prop requirements.

Flow Controls

A flow control valve is a needle valve with a check valve build in it. A needle valve restricts flow in both directions. However flow control valves allow flow go freely in one direction and restrict it in the other direction.

You can connect a flow control valve into a port of a cylinder in two ways. You can restrict flow out of cylinder (metering out) or you can restrict flow into the cylinder (metering in). There are reasons to use one over the other.

When cylinder piston extends, air behind it is compressed because air can't escape easily. When you tighten the flow control screw, movement of the piston slows down because air is restricted even further.

Male Connector Push-On with Flow Control

Screw to your cylinder where the air enters (top, bottom, or both). Simply turn the needle valve to adjust air speed, screw the smaller jam nut to lock in place

In-Line Flow Control

Controls the speed of a cylinder or restricts air flow. Simply turn the needle valve to adjust air speed. We offer two styles, one with push-on’s on both sides and the other with female threads on both sides.

Flow Control with push-on’s. Both sides have push-to-connect fittings; simply push the tubing into each side.

Flow Control with female threads. Both sides have female threads. You could use with our Male Connector Push-On Fittings and then simply push the tubing into each side. Or use with any other type of fittings for your specific application.

Quick Exhaust Valve

Quick exhaust valves are commonly used to increase the speed of cylinders or for rapid depressurization of tanks containing compressed air. The displaced air inside of the cylinder is allowed to exhaust immediately from the Quick Exhaust Valve rather than having to travel back down the airline and our through the solenoid valve.

· 3 ports: air in, air out, and quick exhaust

· All ports are threaded female (available in 1/8, 1/4, 1/2 and 3/4 inch).

· We recommend that a silencer or muffler be mounted on the outlet. Or leave open if used for air blasters.

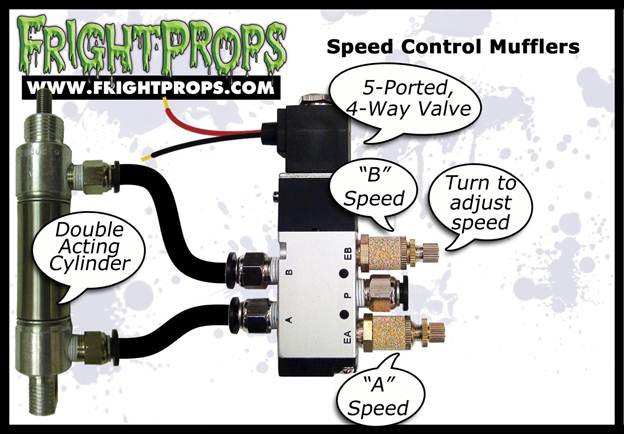

Speed Control Mufflers

The Speed Control Muffler provides infinite metering of air flow by restricting the displaced air inside of the cylinder from escaping. The sintered bronze is encased by an outer metal shroud. With linear adjusting capability, the speed of the cylinder can be decreased by adjusting the integrated screw. When optimal exhaust rate is reached, the lockout may be adjusted to prevent accidental adjustments due to vibration or other means.

WARNING: HYDRAULIC AND PNEUMATIC POWER SYSTEMS CAN FAIL THROUGH MISUSE, AGE OR MALFUNCTION. THE SYSTEM DESIGNER IS WARNED TO CONSIDER THE FAILURE MODES OF ALL COMPONENTS USED IN THE DESIGN AND ENGINEERING OF ALL SYSTEMS AND TO PROVIDE ADEQUATE SAFEGUARDS TO PREVENT PERSONAL INJURY OR DAMAGE TO EQUIPMENT IN THE EVENT OF SUCH FAILURES

- Controllers & Electronics

- Pneumatics

- Electric Motors

- Linear Actuators

- Escape Room Tech

- Video & Visual Effects

- Lighting

- Sound & Audio

- Prop Making

- Talking Skulls

- How To Make Stuff

- Electric Firecrackers

- Decorating Supplies

- Foam Filled Props

- Fog, Fluids, Scents

- Customer Service

- Customer Videos & Pics

- Controller Kits

- Other Things